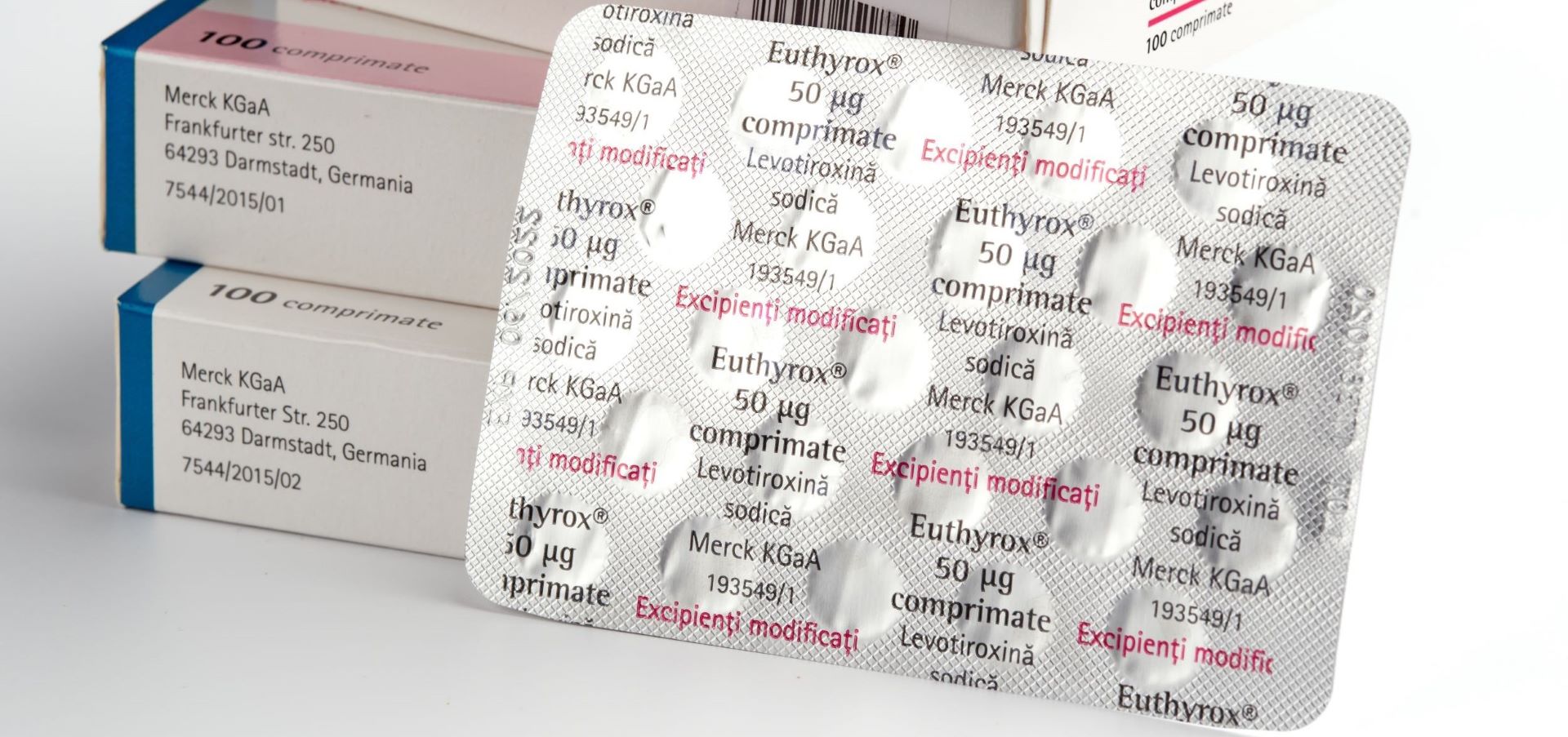

Universal, GMP-Compliant Label Inspection for Pharma, Medtech & Food

UELI is a universal, GMP-compliant label inspection system that ensures flawless labels and full traceability. It automatically verifies text, codes, and graphics, reducing errors and waste while maintaining compliance. Designed for seamless integration into existing printing processes, UELI is ideal for pharmaceutical, medtech, food & beverage, cosmetics, and chemical industries, delivering reliable quality control and peace of mind.

Benefits for your company

Adaptable by design

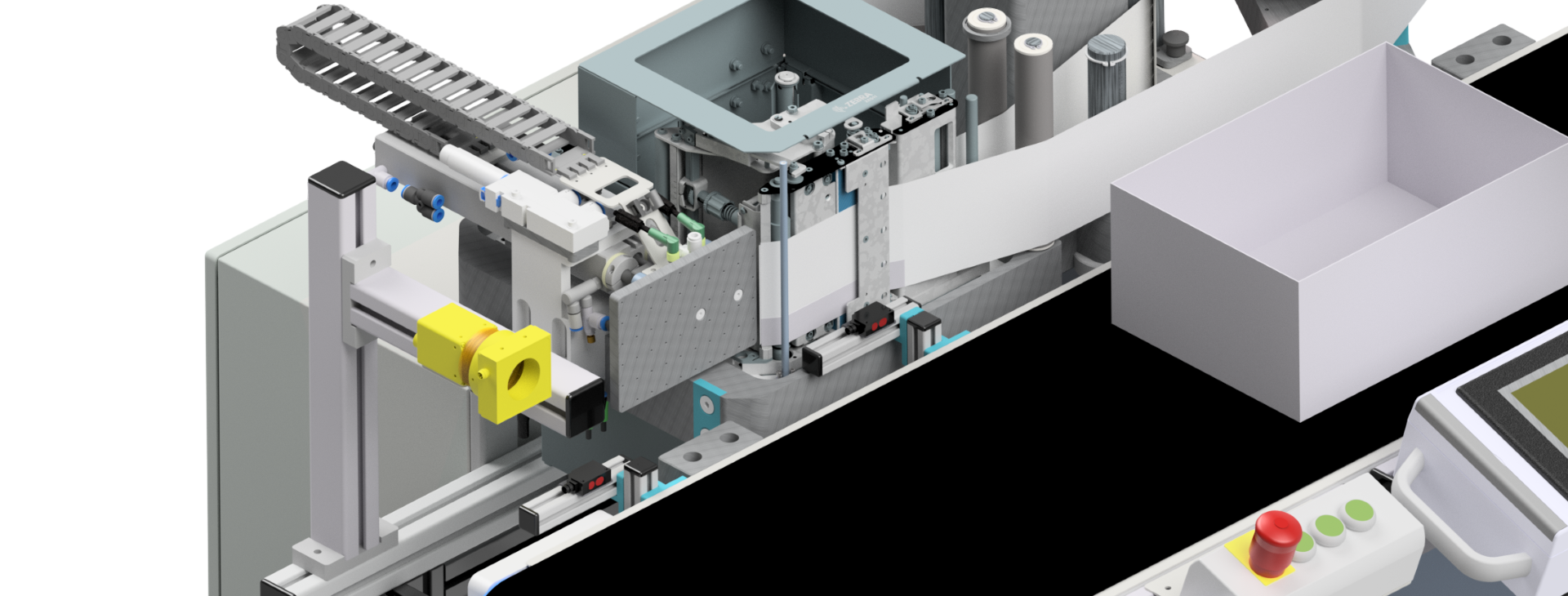

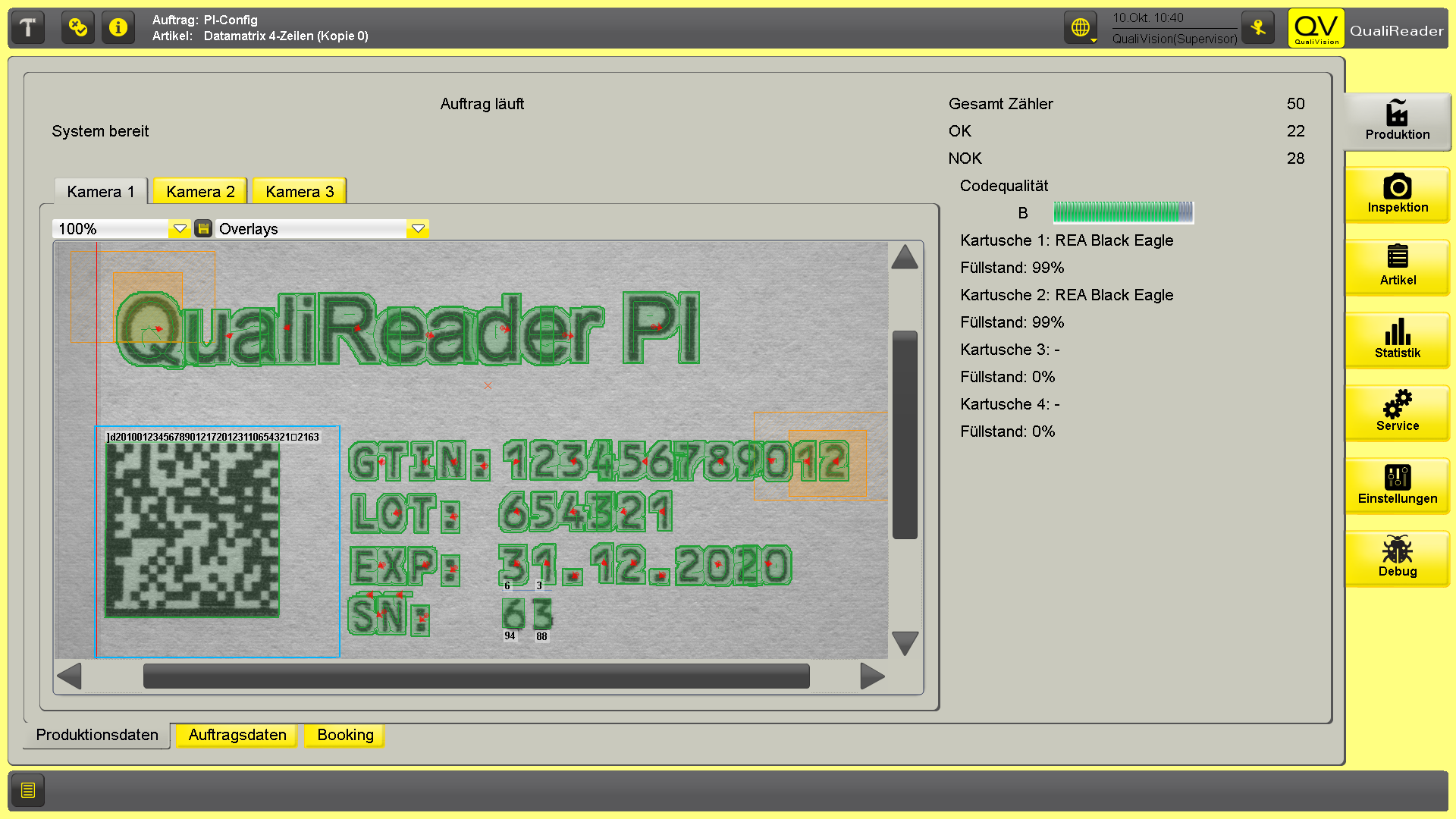

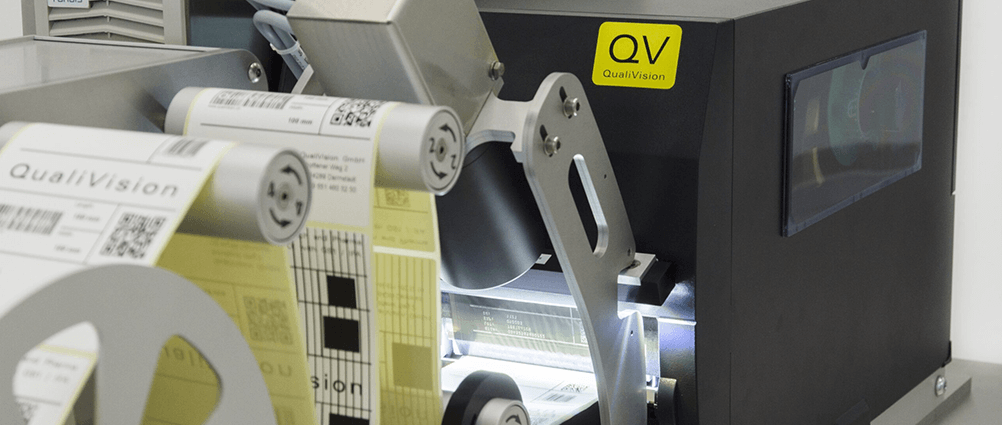

UELI fits into your environment: a height-adjustable inspection station with matrix camera and illumination and an industrial panel PC running QualiReader inspection software. You intend to retrofit your existing print equipment with a vision inspection or you want to build a compact table-top printing cell and you bring the label printer and rewinder. UELI verifies pre-printed elements, codes, text, symbols and variable data so that good labels keep moving and bad ones are stopped.

Digital reference, less setup

UELI works with a digital reference either manually imported or directly from your LMS/ERP via Level 3 or Hotfolder. When the LMS/ERP supplies the digital reference with meta data such as field definitions and formats, QualiReader automatically selects the appropriate inspection method and parameters for each relevant print area. If a digital reference is not directly accessible, simply import a picture or PDF to get going quickly.

Built for your process

Image capture synchronizes to the printer via I/O, ensuring consistent inspection at speed. Orders and articles are managed on the system and can be operated via touchscreen, order sheet (code scanner) or remotely. Results are stored locally on the IPC and can also be mirrored to your database, LMS or ERP for traceability.

Results you can trust

Legibility of static or variable content is checked with PrintControl; codes are read and compared with order data (and optionally classified with a grading approximation); serialized text fields can be verified with OCR/OCV. Out-map masking excludes non-relevant areas to keep performance high and false rejects low.

How UELI works (can be adapted to the customer's process)

Import the layout: Retrieve the digital reference directly from the LMS/ERP via Level 3, or upload a picture/PDF reference manually.

Automatic teach-in: Based on what is printed, where, and in which format, QualiReader automatically chooses the best inspection method for each print area and sets the image-processing parameters.

Label capture: A matrix camera with dedicated illumination records every label, while printer I/O signals trigger the image capture and control the feed.

Handling non-OK labels: If the printer supports overprint voiding and I/O control, UELI voids defective labels automatically. Otherwise, the process pauses, the operator removes the faulty label, and confirms the action in QualiReader.

Documentation: All results are stored on the IPC per order/article, including pass/fail status and statistics, and can also be transferred to your IT systems (database, LMS, or ERP).

PrintControl: GMP‑grade legibility, by design

PrintControl is a geometry‑based, layout‑driven inspection algorithm for static text, logos and artwork. Using the digital reference, it decomposes characters into vector strokes and checks them line by line—delivering an explainable, GMP‑grade legibility score without manual teach‑in. It handles complex scripts (e.g. Arabic, Chinese, Japanese) and touching characters (e.g., “VV”, “Qj”), lets you tune sensitivity per area, and reduces false classifications for faster setup and better auditability.

Hardware in one station.

A height-adjustable mount with alignment guides for fast centering, a matrix camera with matched illumination, an I/O interface for printer trigger and feed, and an industrial panel PC running QualiReader I. You supply your preferred printer & rewinder, so the cell mirrors your current process without any unnecessary re-engineering.

Technical Snapshot

- Inspection methods: PrintControl (low/high sensitivity), OCR/OCV, code read & compare (grading approximation), pre-print/mix-up; maskable out-map areas.

- Integration: Level 3 XML interface, Hotfolder, optional database connections.

- Operation: touchscreen UI, order sheet via code scanner, or remote Level 3 control.

- Data: Orders & Articles with database storage; results local to IPC and optionally pushed to IT systems.

For more information or a demonstration of how our system can help your business, please contact us. We look forward to working with you to make your printing and inspection process safer and more efficient.