In today’s world, it is vital that pharmaceutical, medical device and food companies are able to track their products efficiently and securely. Our Track and Trace vision system including serialization and aggregation provides you with the technology you need to ensure the traceability of your products, increasing safety and compliance.

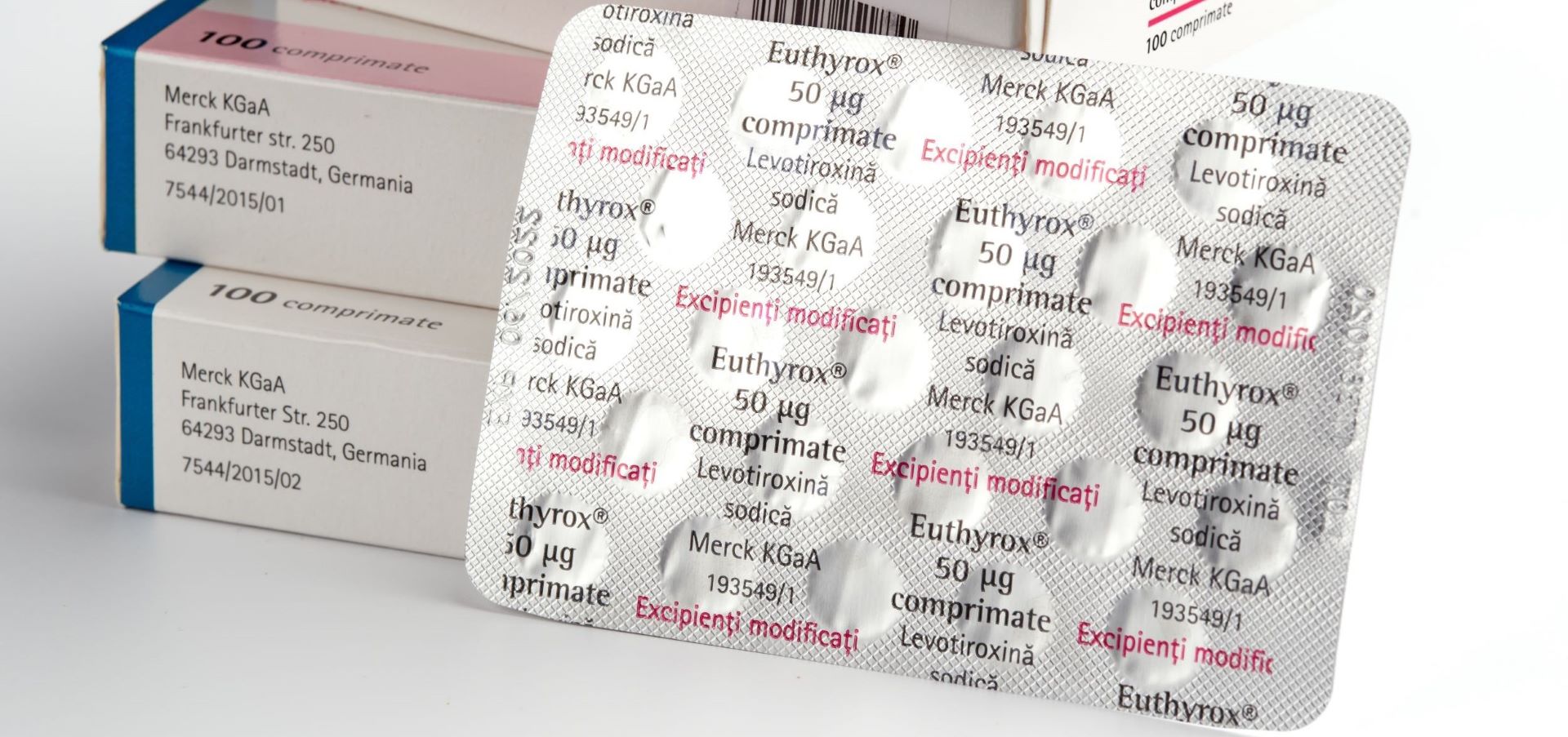

In 2023, the US updated its pharmaceutical serialization requirements in the DSCSA to include unique product identifiers (UPIs) to verify products at the package level, taking a step towards the EM FMD model of drug authenticity modeling.

Other industries, like medtech and food, can look to pharmaceutical serialization to find best practices for their own industries. As branding becomes more of a differentiator, even for consumer packaged goods, it’s important to know where your products are flowing. Implementing a track and trace vision system today helps your business save time and reduce costs, while positioning you for smooth compliance as industry regulations continue to evolve.

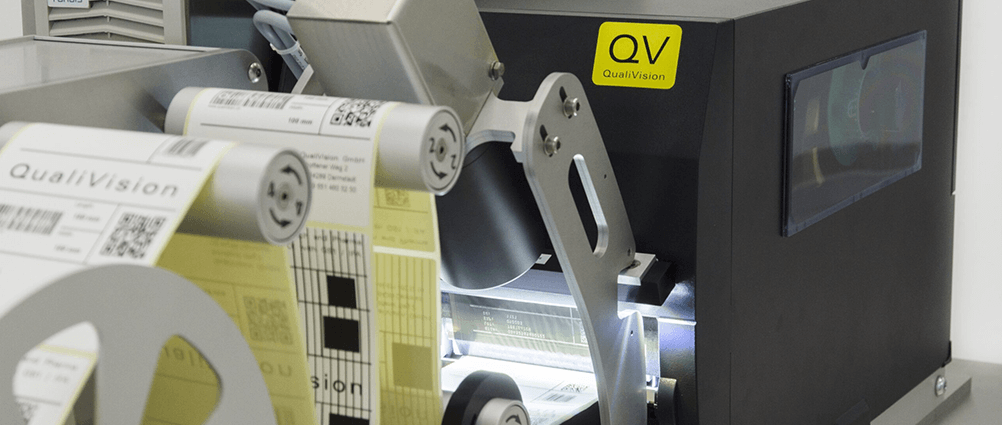

Serialization is the first step of a track and trace solution. It means assigning a unique code to each package of a product, and printing that code on the package. 2D codes (eg. Datamatrix) are ideal for serialization, as they hold essential data in a compact format.

Scanning the code triggers the track and trace function. When implemented correctly, the code provides product details and location to distributors, government agencies, and even consumers. Without serialization, users would be led to information about the product in general.

Sometimes, producers have had to institute recalls. Without serialization, mass recalls take place. With track and trace, companies can more accurately identify potentially hazardous items and remove fewer units.

Alternatively, serialization could also be used for consumer promotions. Currently, packaged food companies often use an individual alphanumeric code printed on each package for sweepstakes and other giveaways. This information could be included in a serialized 2D code instead.

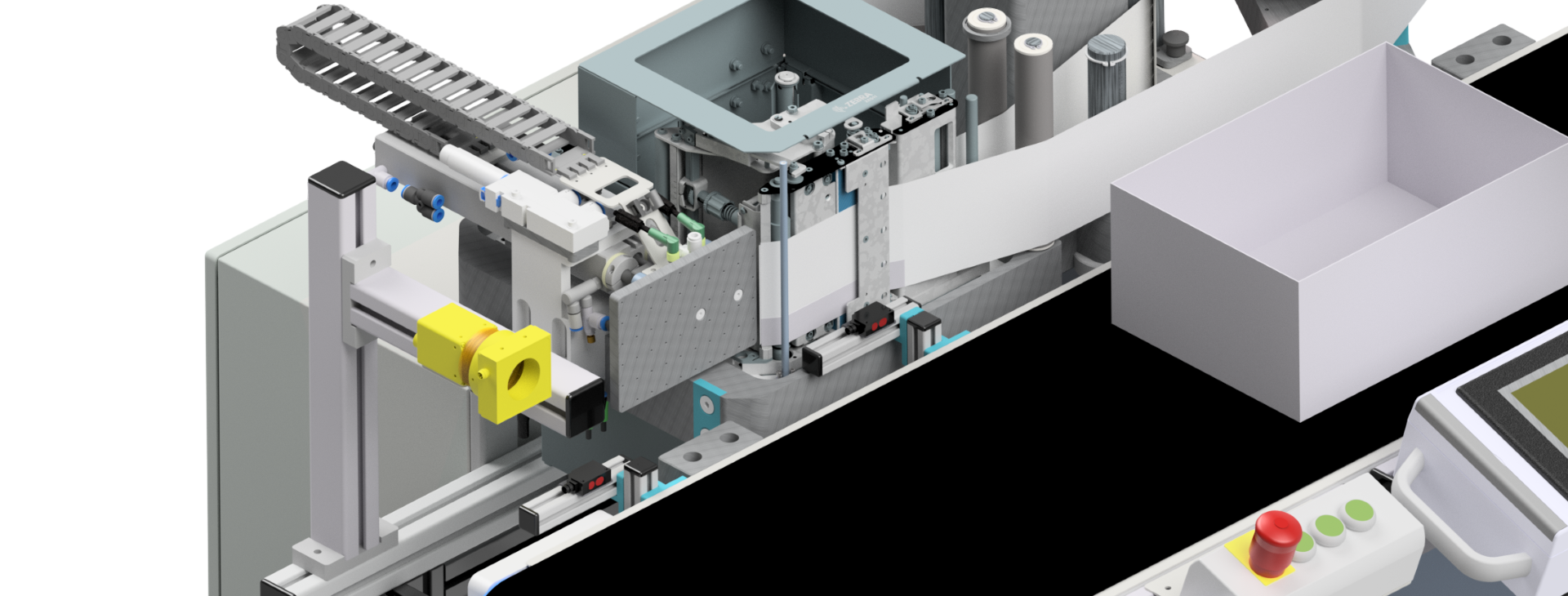

Aggregation builds on serialization by grouping individual serialized units into larger packaging levels – such as boxes, lots, or pallets. This process enables the tracking of product movement at a higher level within the supply chain.

For example, if a head of lettuce in California is found to be contaminated, aggregation allows companies to identify and trace all related units from the same batch or shipment – enabling more targeted and efficient product recalls.

While aggregation is not yet a legal requirement in most jurisdictions, the added visibility it provides is a major advantage. If integrated into a serialization project from the outset, the additional cost is minimal – making it a smart move to consult experts like QualiVision when planning and implementing your serialization and aggregation strategy.

Track and Trace Vision System For Inspection and Compliance

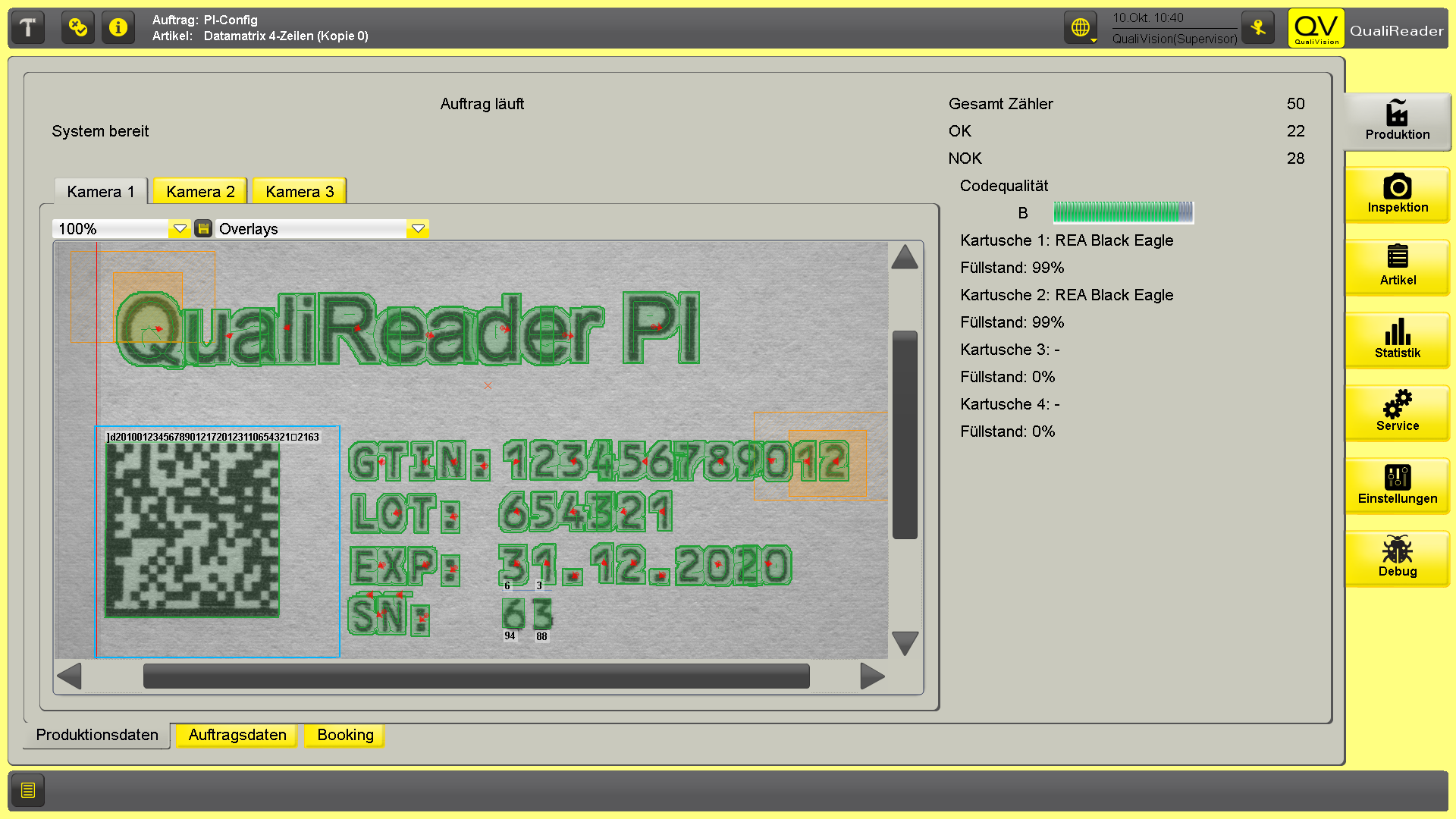

Our Track & Trace vision system, including serialization and aggregation, provides you with the technology you need to ensure the traceability of your products, increasing safety and compliance. Our QualiReader software platform leverages advanced cameras and scanners to accurately capture and track the serial numbers on your products. The system automates seamless monitoring of all items throughout your supply chain. From production to the end consumer, our Track & Trace system ensures that you are always in control and can react quickly if necessary.

A key advantage of our track and trace vision system is the flexibility to connect to different Level 3 suppliers. This level of integration enables efficient processing and exchange of large volumes of data. As a result, you can not only optimize your own data flows, but also communicate seamlessly with suppliers, customers, and regulators. Compatibility with multiple systems reduces technical barriers and promotes effective collaboration across the supply chain.

Track and Trace Vision System Benefits

Safety and

Peace of mind

Accurately track product movements to minimize risks such as counterfeiting or product mix-ups, ensuring full control and confidence in your supply chain.

Regulatory compliance

Comply with the stringent and complex regulations of the pharmaceutical, medical device and food industries in all relevant jurisdictions.

Transparency and customer trust

Ensure complete transparency about the origin and journey of your products, building trust with your customers. This builds lasting trust with your customers and strengthens your brand’s reputation.

Reliability and support

Our commitment does not end with delivery. We provide comprehensive support and ongoing updates to ensure the performance and security of your track and trace vision system.

For more information or a demonstration of how our Track and Trace vision system can help your business, please contact us. We look forward to working with you and to make your supply chain safer and more efficient.